In recent years, the European Union has embarked on an initiative to become the first climate-neutral continent. With a goal of reducing its greenhouse gas emissions by 55% by 2050.

As previously discussed in the article on anti-waste, the European Union has adopted, through the “Green Deal,” a set of legislative measures aimed particularly at implementing the eco-design of sustainable products (ESPR).

One of these measures pertains to the Digital Product Passport (DPP). We’ll tell you more about it in the rest of this article.

Definition

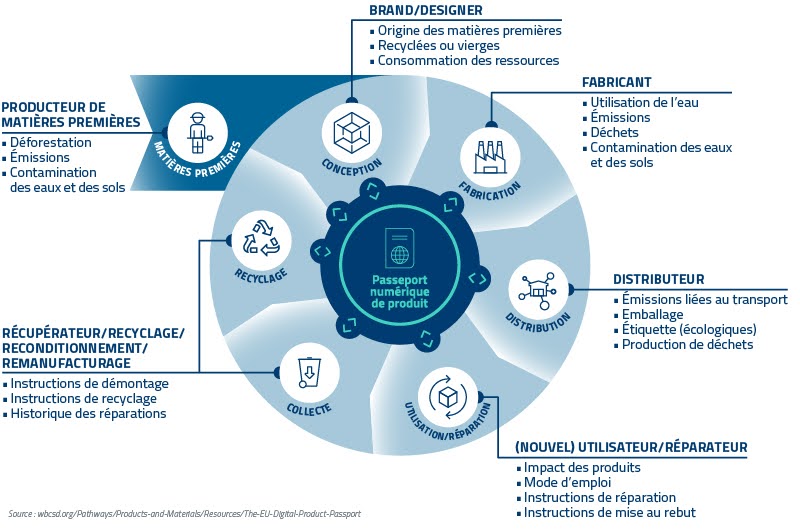

First of all, how do you define a product’s DPP? Quite simply, it’s a secure and unique digital product record, providing a set of information enabling the product to be characterized and traced throughout its entire life cycle.

What product information will be included in the DPP?

This is a mid-2024 list, which could be expanded with additional information in the future:

- Basic Information

Name, brand, batch number, manufacturing date, warranty details, and any relevant information to enhance product traceability. - Composition and Material Origins

Details on its components and the origins of the raw materials used in its composition.

Information on the suppliers involved in its sourcing. - Repairability Information

What is the overall level of reparability of the product, the dismantling of its components and the traceability of repairs that have already been made? - End-of-Life Processing Information

Details of how the product will be handled at the end of its life and how its components and parts will be recycled. - Hazardous and Polluting Substances Information

Indications if the product contains raw materials or components that are hazardous or polluting, impacting its repairability or recyclability. - Environmental Performance Information

Data related to the carbon footprint associated with manufacturing, distribution, and usage processes.

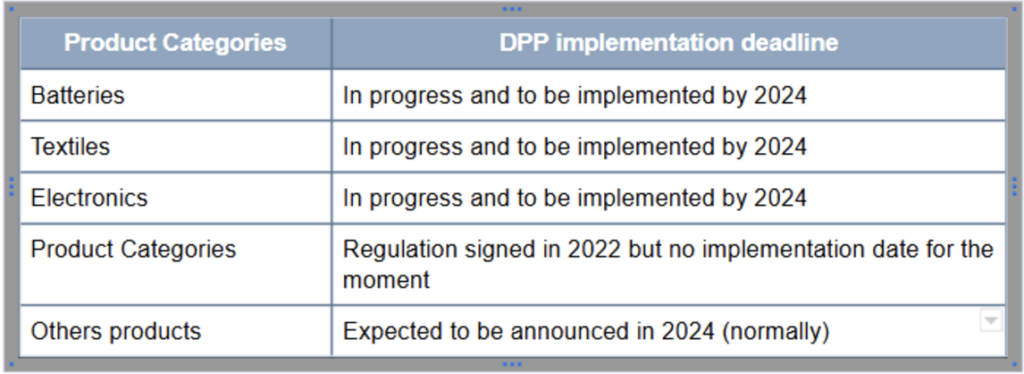

What are the implementation deadlines?

The Digital Product Passport (DPP) is currently a proposal rather than an obligation, published on March 30, 2022, by the European Commission as part of the Eco-design for Sustainable Products initiative.

In terms of timeline, the initiative aims to begin with three sectors—batteries, textiles, and electronics—by 2026 before expanding to over 30 product categories on a timeline that has not yet been clearly defined.

As we will see, the impacts are so significant for the stakeholders involved that a “big bang” approach would simply be unfeasible.

The first principle validation for batteries (industrial and electric vehicle batteries) was unveiled at the 2023 Economic Forum in Davos (link to an English page).

What does the DPP look like?

The implementation of the DPP will first and foremost require the collection of product data.

Next, it will be necessary to store and provide easy access to this information for all stakeholders involved.

A secure storage system, much like any passport, will be required, with an entry point in the form of an ID acting as a license plate, granting access to all the product’s information.

What media should be used for this number plate? Here are the most popular in September 2024:

The QR Code

A system already widely used by many companies, it offers the advantages of being durable, flexible, and easy to read using a smartphone or PDA.

The barcode

Historically, this has been the most widely used device since the 1980s. The disadvantage is that it is less flexible in terms of data access.

The RFID tag

In addition to the fact that an RFID tag is not necessarily visible to the naked eye like a QR Code or Barcode, it has the advantage of being much more secure than its counterparts, in particular with the concepts of authentication and proof of falsification.

The digital punch

This is a Franco-Swiss invention based on the principle of the hallmark in the watchmaking industry. It ensures authenticity through a unique marking. Developed by Ocode: https://www.ocode.fr/poincon-numerique

The choice will depend on the use case and the type of product. In the luxury sector, where counterfeiting remains a scourge, the RFID tag seems to be a good solution.

In practical terms, how does the DPP work?

Let’s take a concrete example with the O2feel brand, which specializes in the sale of electric bicycles and has opted to use Ocode’s digital stamp.

To access the DPP for the product you have just bought :

- First you need to find the digital stamp, which is either engraved on the product itself or on a card given to you when you buy it.

- Go to the O2feel website and scan your digital punch or enter the authentication ID

Validating the digital stamp then gives you access to a digital safe containing all the information contained in your bike’s DPP.

The objectives of the DPP:

The main aim of the DPP is to improve the sustainability and circularity of products in the European Union by :

- Encouraging purchase decisions based on environmental sustainability

- Enabling better traceability and improved environmental impact

- Facilitating waste management by promoting widespread recycling

- Allowing greater control over energy and resource consumption

In essence, the goal is to establish a virtuous cycle and reduce rampant consumerism.

Advantages for companies:

- Ensuring product compliance with European regulations

- Positioning themselves as truly responsible and transparent players, enhancing their reputation while avoiding associations with greenwashing

- Optimizing their supply chain, particularly by reducing the opacity of exchanges between all supply chain stakeholders

- Building a strong connection with customers through the argument of eco-responsibility, while also using the DPP as a certificate of authenticity and ownership to mitigate the significant risk of counterfeiting, especially in the luxury sector.

Beneficial for consumers:

- Empower customers by providing them with an effective tool to guide them in their purchasing choices;

- Reduce their ecological footprint by extending the life of the goods they buy, thanks to information on repairability and recycling;

- Reassure the customer of the authenticity of the product purchased.

It is likely that the DPP will also bring benefits to other players in the chain:

- Materials suppliers, who will benefit from greater visibility as a reward for transparency in their management of environmental safety;

- Professional repairers, who will be able to use the history of renovations to ensure that repairs are more efficient and last longer;

- Recycling circuits, which will have more detailed information on components and hazardous products, and will be able to improve and secure the recycling of components;

- Public authorities, who will be able to rely on a new tool to check product conformity.

Impact of the DPP on businesses

First and foremost, it is important to understand that even if the DPP is not mandatory at the moment, companies will eventually have to implement this standard in order to be able to sell on the European market.

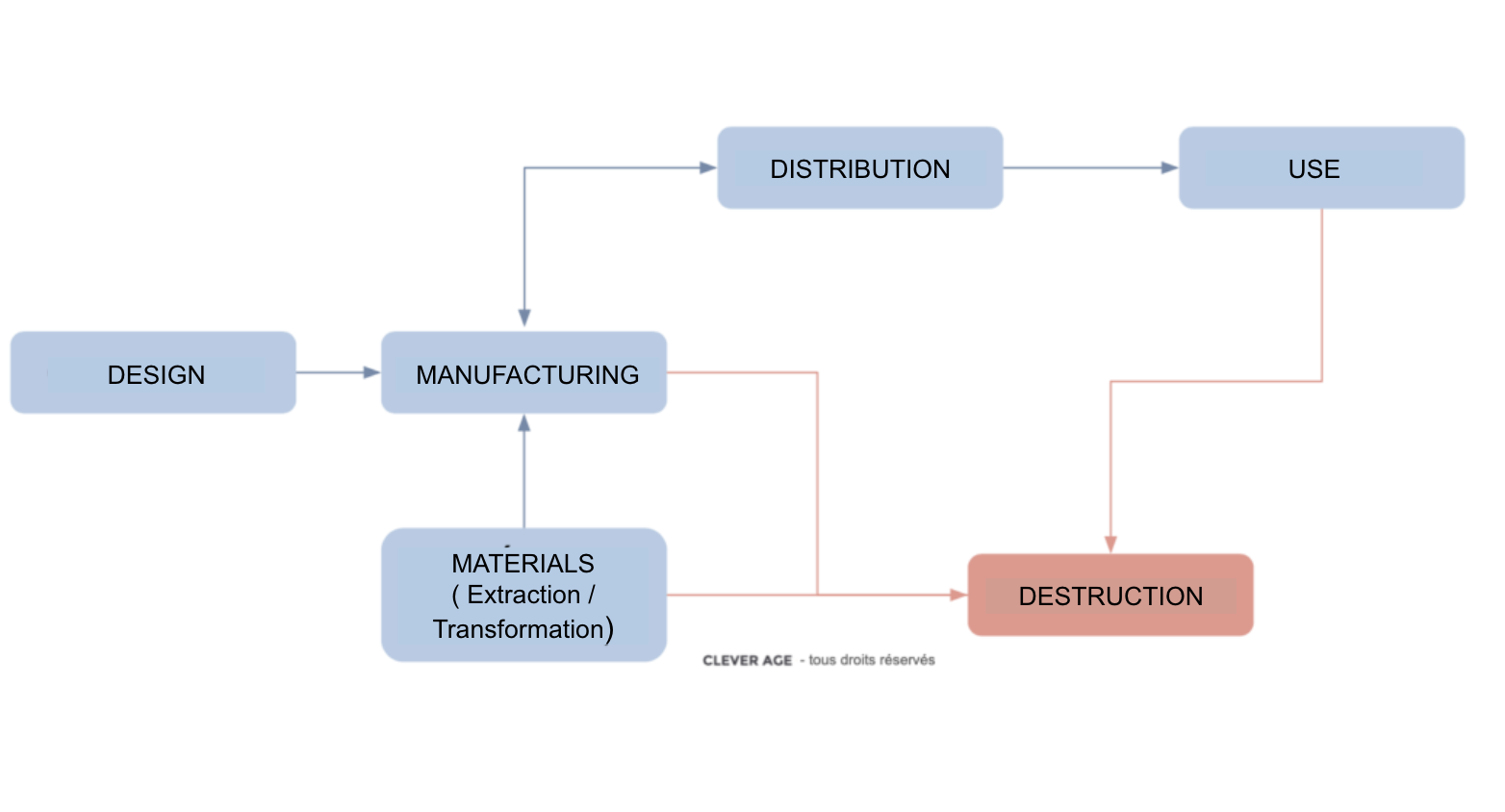

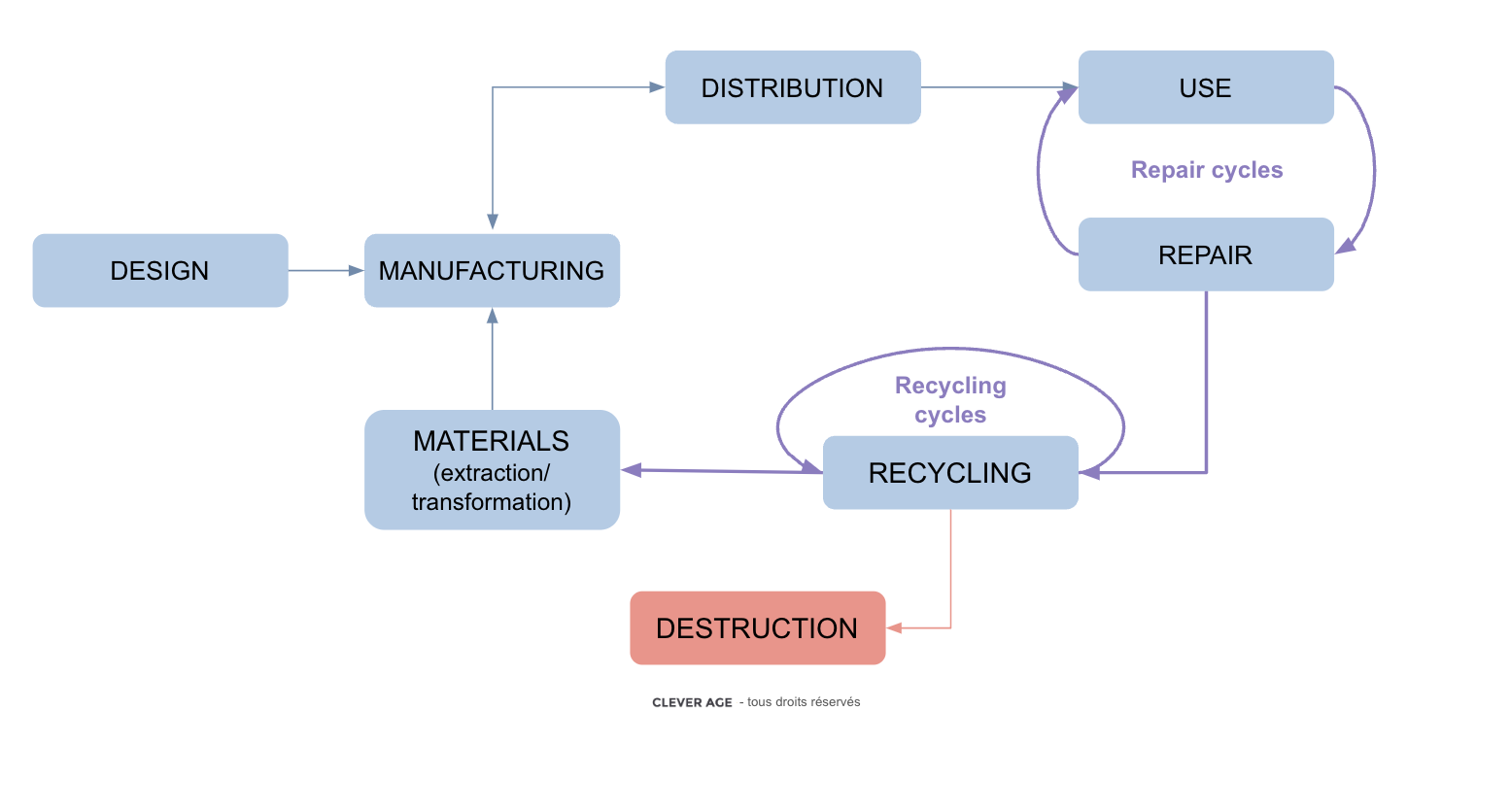

Secondly, the DPP introduces a new product life cycle aimed at making repairability and recycling more widespread.

This is not a simple model transition, as it requires the integration of new players, new processes, new communication channels between software bricks and new product reference data.

Simplified diagram of a “classic” product life cycle

Conception = design

Fabrication = Manufacturing

Materiaux = Materials

Utilisation = Use

Simplified diagram of a “sustainable” product life cycle

It is clear from this diagram that repair and recycling complicate the calculation of environmental impact, for example by multiplying the data points on a product made of several materials whose recycling times will not necessarily be equivalent.

Finally, even though the practical implementation of the DPP is still unclear for virtually all the players involved, it is clear that the DPP data is the product’s reference data.

As such, this data is heterogeneous and will come from a wide variety of sources, as it concerns several areas: materials, manufacturing, processing, transport, etc.

In addition to having reference data organized in silos of activities inside and outside your IS, it will be important to determine, between all these silos, the “final truth” data to be stored in the DPP. For example, a supplier’s traceability or sustainability data could take the form of a certificate, a tax payment or simply supplier account information.

This decentralized, non-standardised management by different departments makes it virtually impossible to implement transparency and traceability.

The first challenge, therefore, is to centralize and standardize data for the DPP, making it possible to de-duplicate, standardize, clean up, apply business rules, report and expose a ready-to-use repository for all players.

Faced with this situation, over and above defining whether your PLR will be a QR Code or an RFID tag, you need to define which part of your IS will be responsible for the governance of DPP data throughout the life of your products.

From experience, when it comes to the notion of a product repository, specialized bricks such as PLM, MDM or PIM come to mind.

Some of these players are already positioning themselves on the subject, as demonstrated in May 2024 by the merger between Akeneo (a PIM solution) and OCode, a DPP solution provider (https://www.lesclesdudigital.fr/akeneo-cree-une-application-dpp-avec-ocode/).

The choice can only be made on the basis of an in-depth study of your IS, your supply chain, the channels through which product data is collected and the efforts and processes to be implemented to extract clean data that can be shared with all the players involved and accessed in a way that is legible for your end customers.

In conclusion

It seems clear that in the years to come, implementing the DPP will be a major challenge for companies and all their partners.

As we have seen, there are many impacts, many benefits and many pitfalls.

While the outlines are beginning to become clearer, its application still reveals areas of vagueness and uncertainty:

- How can the relationship with repairer and recycler networks be integrated so that repair histories and recycling information can be retrieved?

- In the case of second-hand sales, will sellers also be required to provide information on the length of ownership of their products?

- How can we make the supply chain, which has long seemed opaque to all those involved, more transparent?

- Will it be easy to collect data on all products, and will we be talking about one DPP or DPPs for each product sector? This could make day-to-day management more complex.

- Should the DPP apply to the product, to the same batch or to a product model rather than to its variations?

- What KPIs and monitoring reports should be implemented so that companies can make the most of DPP data?

- Whatever the case, this is an important subject that will revolutionize the way products are managed for a long time to come.

Don’t hesitate to contact us to discuss it together!